Diamond grinding wheels are generally composed of a diamond abrasive layer, a transition layer and a matrix.

The quality of diamond abrasive directly affects the quality of the grinding wheel. Most of the ceramic diamond grinding wheels we produce are used for grinding and polishing,

so we use more micro-powder-grade materials. The control of diamond micro-powder particle size is particularly important.

The aspect ratio of diamond micro-powder particles should generally not be greater than 1.5 times, and there should be no over-wide particles.

As long as there are oversized coarse particles, it will cause scratches on the workpiece, making the work of the previous process useless.

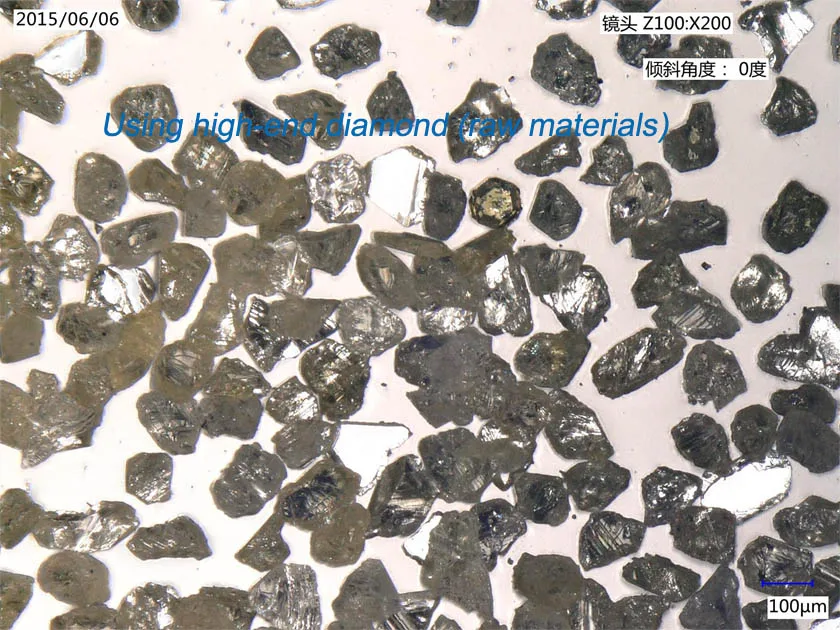

Therefore, the correct size should be as shown in the figure below:

If defective raw materials are used to make grinding wheels, the quality of the PCD tool edge is unstable and prone to chipping.

Therefore, micro powder quality inspection is an important part of ensuring the quality of grinding wheels.

To ensure that our grinding wheels can maintain a good stability of the edge quality, tool life and cutting efficiency of the processed tools from the beginning to the last 1mm.

However, some defects of materials cannot be observed by the naked eye. There are many instruments available for measuring the particle size of micro powders.

Good micro powders are observed under a microscope, with good transparency, a transparent core surrounded by a black edge outline, and relatively high strength;

micro powders that are completely black have many impurities and inclusions inside, and relatively low strength.

To achieve a better grinding effect, the material must be round, well concentrated, and thick.

Most of the diamond grinding wheels produced by our company are used for grinding and polishing of carbide tools.

Usually, they are tested according to the customer's requirements. Through our tests, we found that if some thin materials are mixed into the material,

the grinding wheel density will be uneven when pressing the grinding wheel, which will cause diagonal cracks.

Moreover, such cracks are invisible and cannot be observed on the surface. However, if the pressed material ring is broken, it will be found that it will break along the cracks.

When customers use this grinding wheel to process workpieces, the cracks will easily break and accidents will occur.

If the strength of the material is relatively low, the particle size is uneven, or there are many thin slices, after sintering,

the material ring will expand severely, resulting in insufficient hardness of the grinding wheel and excessive size,

which will reduce the life of the grinding wheel and the number of processed tools will also be sharply reduced.

And so on. Our goal is to help our customers become more trusted suppliers for end users.

We realize that we must start from the source of the material. If the raw materials are not well controlled, no matter how hard we try, it will only be half the result with twice the effort.

After a series of experiments and discussions with industry experts, we selected high-quality diamond raw materials for each batch of products.

Although the price exceeded our expectations, we were still very happy to accept it because of the improvement of our product quality.

Now we still insist on doing experiments for each batch of orders, and only formally produce orders after the experiments are successful;

they must be tested before leaving the factory, and only after the tests are qualified can they leave the factory. We must also work hard to be a reliable and stable supplier.